Created: 08/03/10 by EF Updated: 09/30/11 by EF

Current mirror surface: why we do this, June 2010:

Refractory base assembly at the center of the SOML furnace floor, 20 Jul 2010:

Refractory base assembly, close-up, 20 Jul 2010:

Refractory base assembled, with partial side wall, 20 Jul 2010:

Refractory base assembled, lonely at the center of the furnace floor, 30 Jul 2010:

Refractory base, Falco and Brocious for scale, 30 Jul 2010:

Refractory base assembled, with full side wall and shaper, 13 Aug 2010:

Refractory base and mold assembled, with full view of shaper, 13 Aug 2010:

Core element machined, 13 Aug 2010:

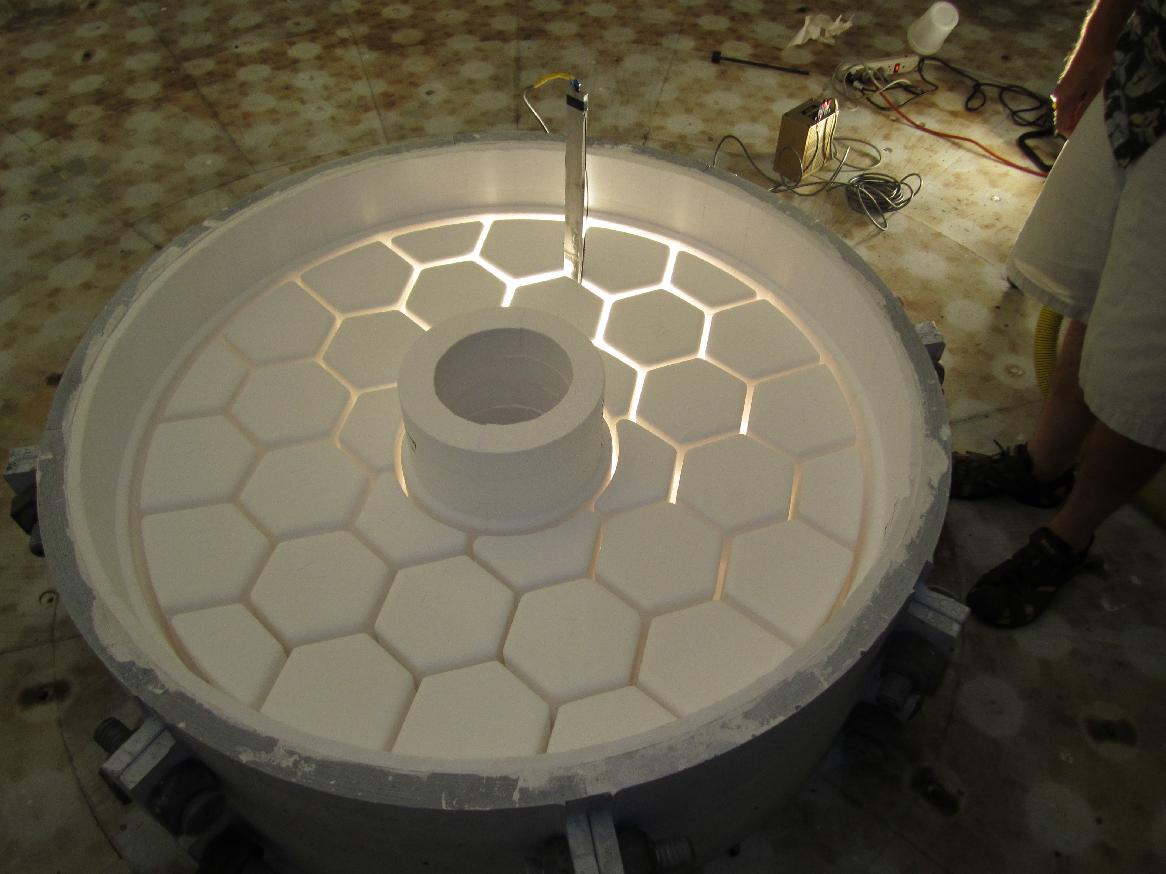

Core elements assembled, furnace ready to go, 19 Aug 2010:

Close-up of the core elements in the mold, 19 Aug 2010:

Cleaning post-pre-fire, 31 Aug 2010:

Inspection post-pre-fire, 31 Aug 2010:

Ohara E6 glass ready to load in the mold, 31 Aug 2010:

Looking into the furnace, 31 Aug 2010:

Ohara E6 glass loaded in the mold, 02 Sep 2010:

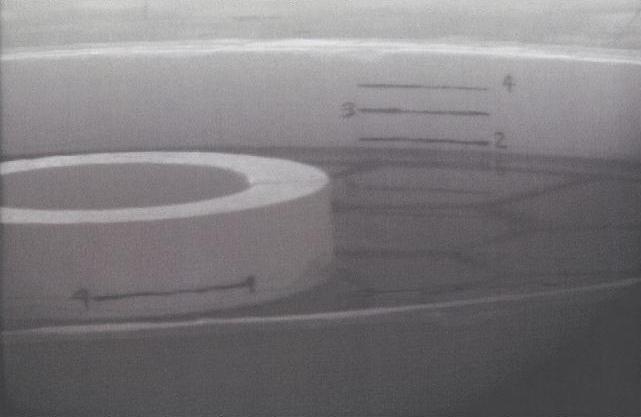

Glass molten in the mold at about 1155C, about to start cooling, 10 Sep 2010:

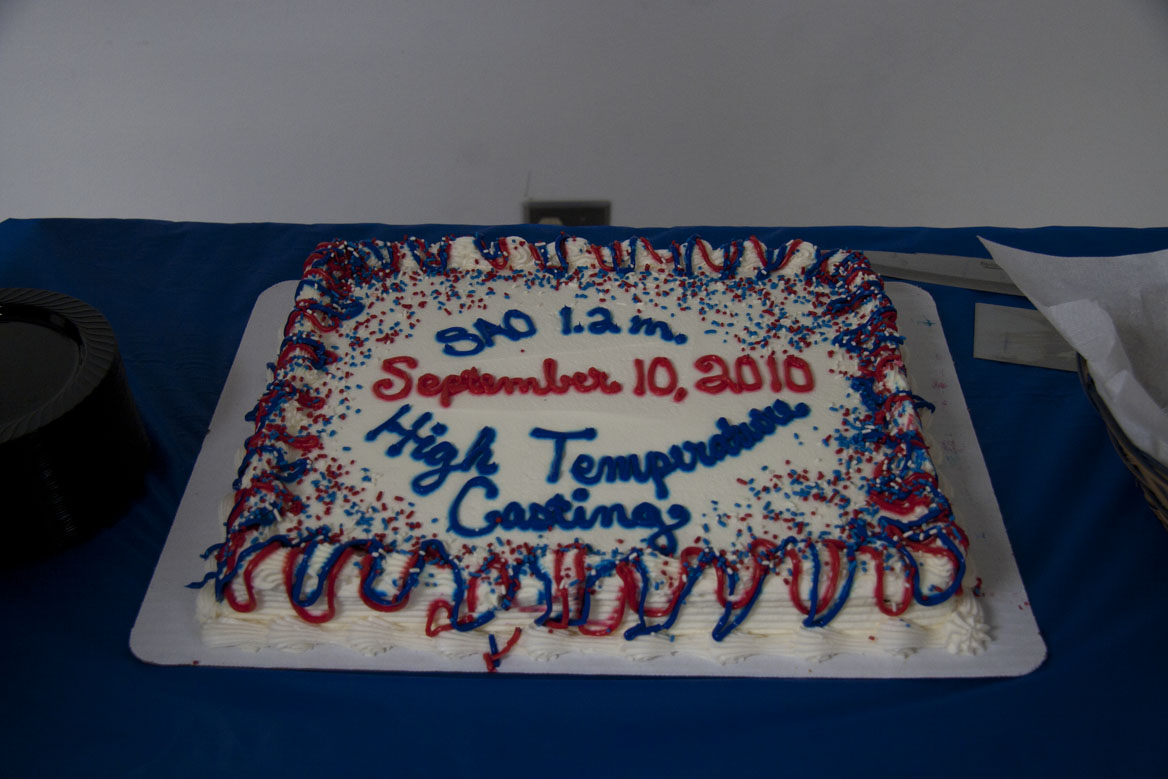

Celebratory cake at SOML, 10 Sep 2010:

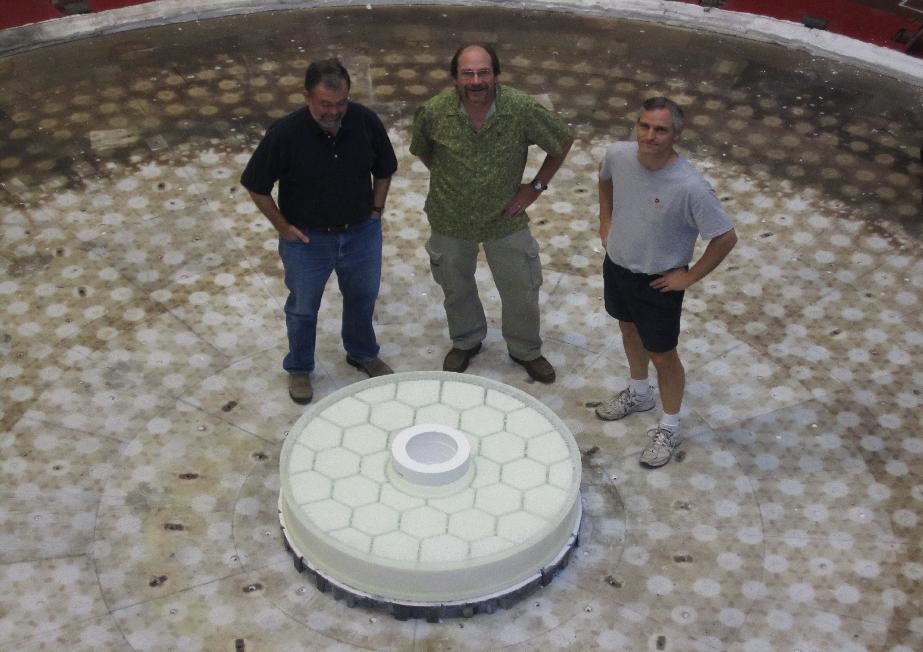

Furnace is open, inspection of the glass, 19 Oct 2010:

Witnesses: Falco, Brocious, Lutz, shot by Kingsley, 19 Oct 2010:

The backside of the blank is ready for figuring, 08 March 2011:

The backplate of the blank is being generated and beveled; the side is also ground. The side of the central hole is worked on, 15 April 2011:

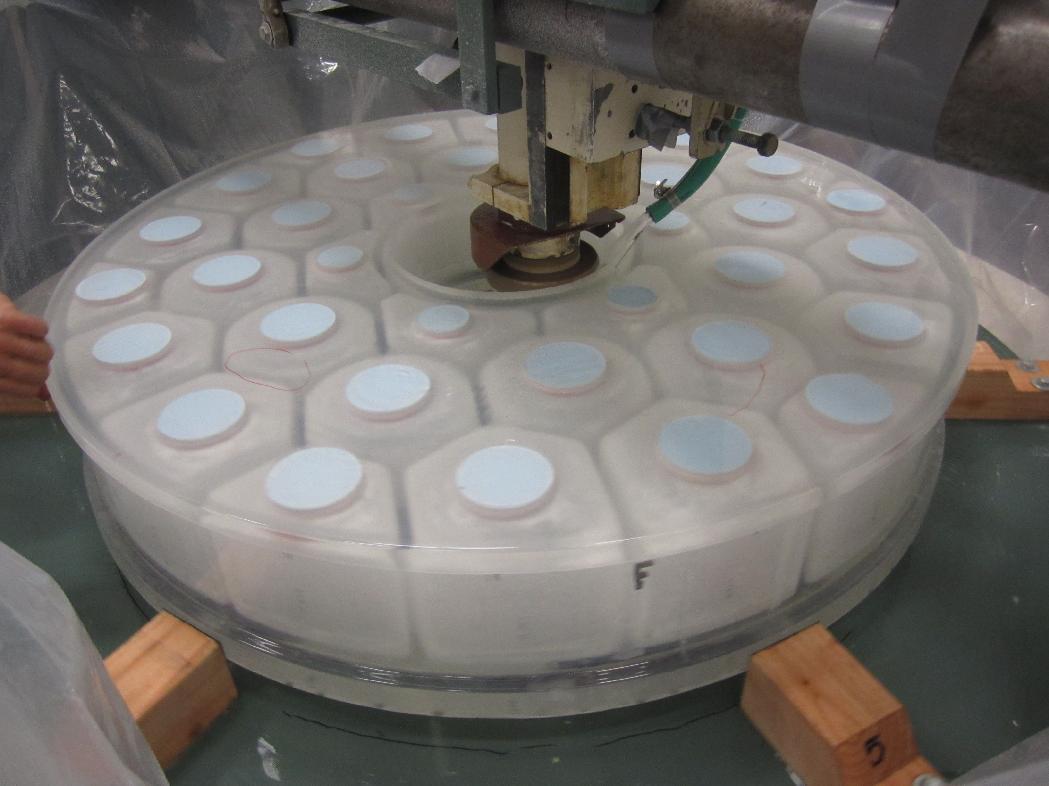

The backplate of the blank is generated and is now undergoing loose abrasive grinding, 22 April 2011:

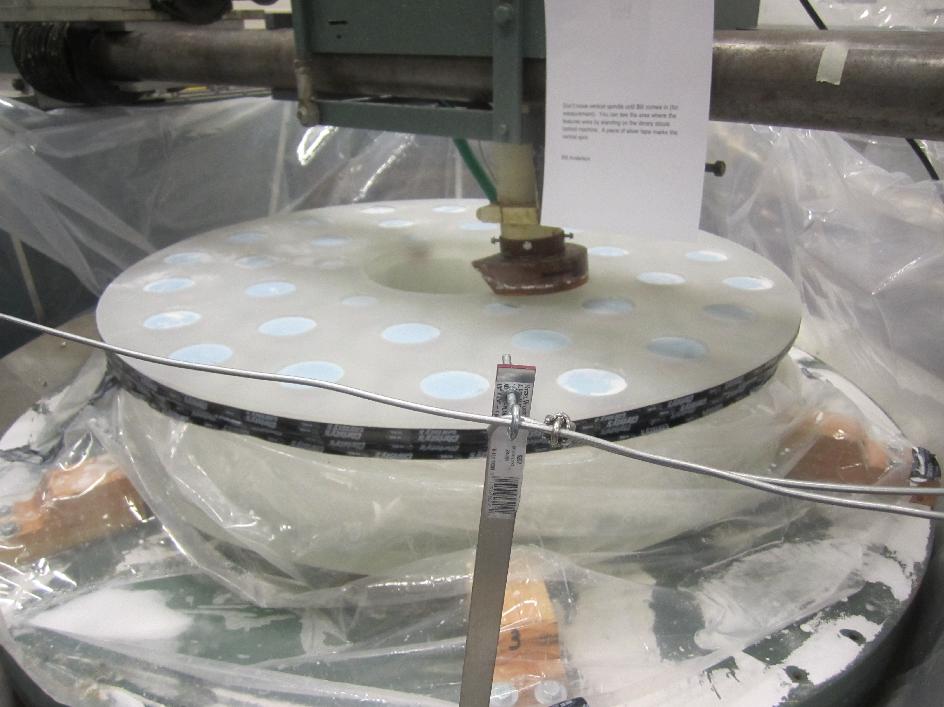

The backplate of the blank is in the last phase of loose abrasive grinding, with polishing set to start the week of 02 May 2011:

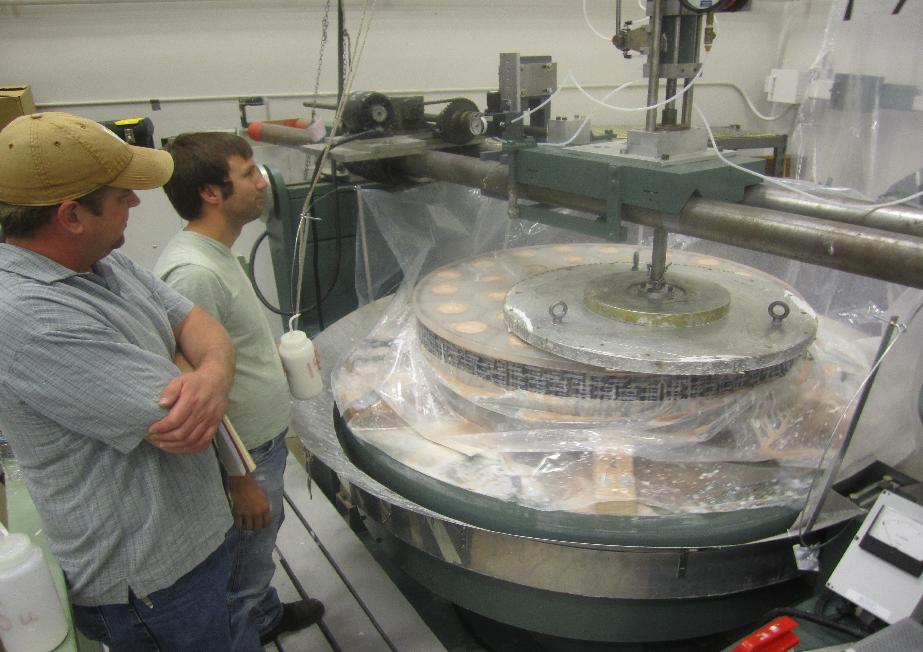

Don Loomis has been working hard on our mirror, as shown in the image taken on 23 Sept 2011: